AVK UNDERGROUND FIRE HYDRANT, PN16

R7, with backflow protection, DN80

Contact

AVK International A/S

Bizonvej 1, Skovby, 8464 Galten, Denmark

Underground fire hydrant to EN 14339 and KIWA BRL-K614-04 for drinking water and neutral liquids to max. 60° C

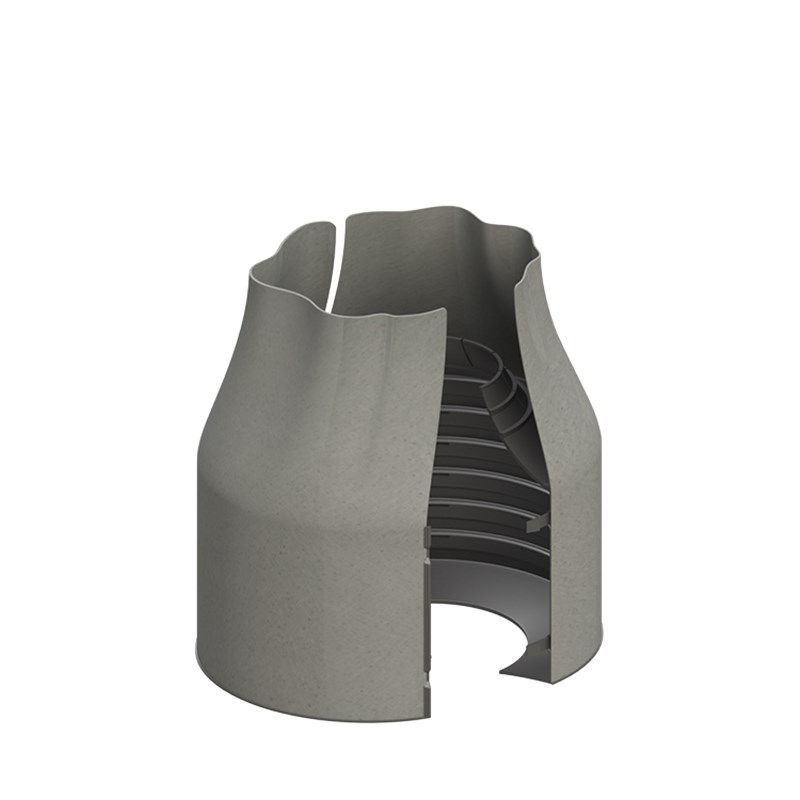

AVK Series 35/57 underground hydrants are equal to high quality in every detail and meet or exceed the requirements of DIN/EN14339. The shutoff plug is vulcanized with EPDM. The integrated check valve serves as a security device that protects against backflow and pollution of the drinking water system .

| Variant 35/57-001 | |

|---|---|

| Connection: | Flanged |

| Material: | Ductile Iron |

| DN: | DN80 - DN80 |

| PN: | PN16 |

| Closing direction: | Clockwise to Close |

Features

- Frost-proof automatic drainage in flush proof design

- Axial sealing valve seat ring in stainless steel (optionally in dezincification resistant brass)

- Backflow-protection

- Disc with ductile iron core coated with EPDM

- Stem bearing with polyamide antifriction washer that secures an easy and smooth operation

- Fusion bonded epoxy coating in compliance with DIN 3476 part 1 and EN 14901, GSK approved

- Kv value: 123 m³/h

- Drainage: Time for drainage: 52 sec.

Downloads

Datasheet

Certificate(s)

Reference nos. and dimensions:

Scroll for more info

| AVK ref. no. | DN mm |

Pipe cover mm |

H3 mm |

W mm |

L1 mm |

L mm |

L2 mm |

Theoretical weight/kg |

|---|---|---|---|---|---|---|---|---|

| 35-080-57-11024 | 80 | 750 | 472 | 180 | 246 | 273 | 120 | 24 |

| 35-080-57-21024 | 80 | 1000 | 722 | 180 | 246 | 273 | 120 | 27 |

Enquiry

Scroll for more info

Components

| 1. | O-ring | EPDM rubber |

| 2. | Leaf membrane | EPDM rubber |

| 3. | Bayonet coupling | Ductile iron GJS-500-7 (GGG-50) |

| 4. | Stem cap | Ductile iron GJS-500-7 (GGG-50) |

| 5. | Split pin | Stainless steel 1.4301 |

| 6. | Identifier disc | Plastic |

| 7. | Bonnet | Ductile iron GJS-500-7 (GGG-50) |

| 8. | O-ring | EPDM rubber |

| 9. | Washer | POM GF25 |

| 10. | Operation pipe | Stainless steel |

| 11. | Hydrant body | Ductile iron GJS-500-7 (GGG-50) |

| 12. | Bolt | Stainless steel A2 |

| 13. | Washer | Stainless steel A2 |

| 14. | Drain pipe | Polyamide |

Test/Approvals

- Hydraulic test according to EN 1074-6 / W 386-P

-

Hydraulic test according to EN 1074-6 / VP325

Approved according to KIWA Reg.no. K6122/06

- Approved according to CE Reg. No. 0620-CPR-6122

Standards

- Designed according to EN 14339 and KIWA BRL-K614-04

- Standard flange drilling to EN1092-2 (ISO 7005-2), PN10/16