AVK SERVICE CONNECTION VALVE, DI, PN16

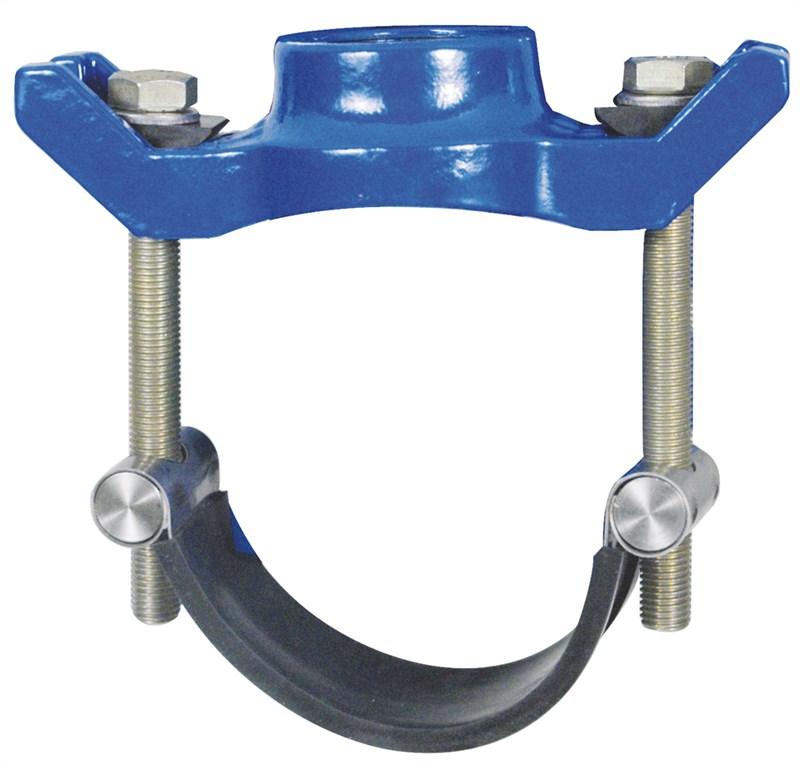

Tensile screw couplings for PE pipes, DN25-50

Contact

AVK International A/S

Bizonvej 1, Skovby, 8464 Galten, Denmark

Service connection valve with tensile screw couplings for PE pipes. For drinking water and neutral liquids to max. 20° C. Note: The maximum working temperature is set according to the ISO9080 lifetime requirements for PE pipes, and is therefore not the max. temperature for the valve.

AVK resilient seated service connection valves are designed with built-in safety in every detail. The wedge is vulcanized with AVK’s own drinking water approved EPDM rubber compound. It features an outstanding durability due to the ability of the rubber to regain its original shape, the double bonding vulcanization process and the sturdy wedge design. The triple safety stem sealing system, the high strength stem and the thorough corrosion protection safeguard the unmatched reliability.

| Variant 03/65-005 | |

|---|---|

| Connection: | Tensile Screw Couplings for PE Pipe |

| Material: | Ductile Iron |

| DN: | DN25 - DN50 |

| PN: | PN16 |

| Closing direction: | Clockwise to Close |

Features

- Wedge of brass CW626N vulcanized with EPDM rubber – both brass and rubber certified for use in contact with drinking water– and shaped with guides and a special rubber profile ensuring low closing torques

- Stainless steel stem with rolled threads providing high strength

- Full circle thrust collar provides fixation of the stem and low free running torques

- Stem sealing with an NBR wiper ring, a polyamide bearing with four NBR O-rings and an EPDM rubber manchette

- EPDM bonnet gasket fixed in a recess

- Countersunk and sealed stainless steel bonnet bolts encircled by the bonnet gasket

- Full bore

- Low operating torque

- Coupling nut of dezincification resistant brass, tension ring of brass and sealing ring of EPDM rubber

- Fusion bonded epoxy coating in compliance with DIN 3476 part 1 and EN 14901, GSK approved

Downloads

Reference nos. and dimensions:

| AVK ref. no. | DN mm |

Dd mm |

Product PN Class |

L mm |

H mm |

F mm |

F1 mm |

F2 mm |

Theoretical weight/kg |

Notes |

|---|---|---|---|---|---|---|---|---|---|---|

| 03-032-65-0046499 | 25 | 32 | PN16 | 133 | 165 | 12 | 15 | 35 | 2.7 | Approval pending |

| 03-040-65-0046499 | 32 | 40 | PN16 | 140 | 176 | 12 | 15 | 35 | 3.0 | Approval pending |

| 03-050-65-001 | 40 | 50 | PN16 | 170 | 203 | 12 | 15 | 35 | 5.8 | |

| 03-063-65-001 | 50 | 63 | PN16 | 184 | 213 | 12 | 15 | 35 | 7.2 |

Components

| 1. | Stem | Stainless steel 1.4104 (430F) |

| 2. | Wiper ring | NBR rubber |

| 3. | O-ring | NBR rubber |

| 4. | Bearing | Polyamide |

| 5. | Bonnet | Ductile iron GJS-500-7 (GGG-50) |

| 6. | Thrust collar | Brass, DZR CW602N |

| 7. | Manchette | EPDM rubber |

| 8. | Bonnet bolt | Stainless steel A2, sealed with hot melt |

| 9. | Bonnet gasket | EPDM rubber |

| 10. | Wedge | Brass, DZR CW626N with EPDM |

| 11. | Body | Ductile iron GJS-500-7 (GGG-50) |

| 12. | Coupling nut | Brass, DZR CW602N |

| 13. | Tension ring | Brass, DZR CW602N |

| 14. | Seal ring | EPDM rubber |

Test/Approvals

- Hydraulic test according to EN 1074-1 and 2 / EN 12266 |

- Seat: 1.1 x PN (in bar), Body: 1.5 x PN (in bar). Operation torque test

- Belgaqua approved

- Approved according to ACS Certificate 18 ACC NY 369

- Approved according to Swedish type approval 1350 certified by KIWA

Standards

- Designed according to EN 1074 part 1 & 2, Designed according to EN 1171